On Demand Webinar Ultrafast Optics: Challenges and Solutions view now

|

|

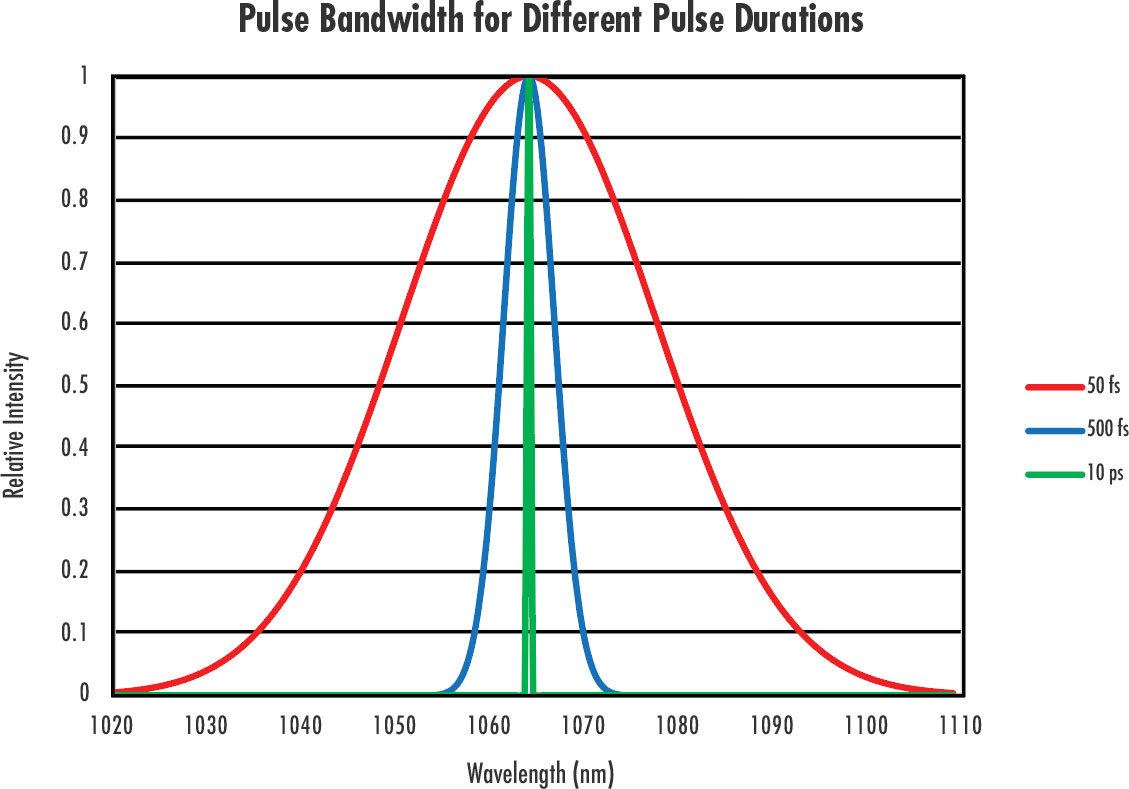

Ultrafast lasers emit extremely short pulses, resulting in a wider wavelength spectrum compared to that of most lasers |

|

|

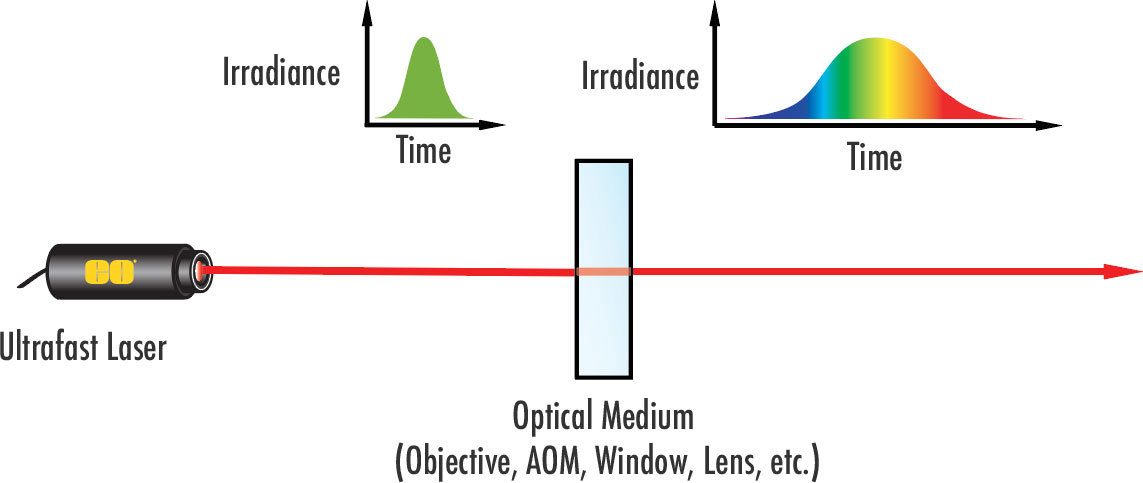

Dispersion in optical components, such as microscope objectives, increases the pulse duration, which is detrimental for ultrafast applications |

|

|

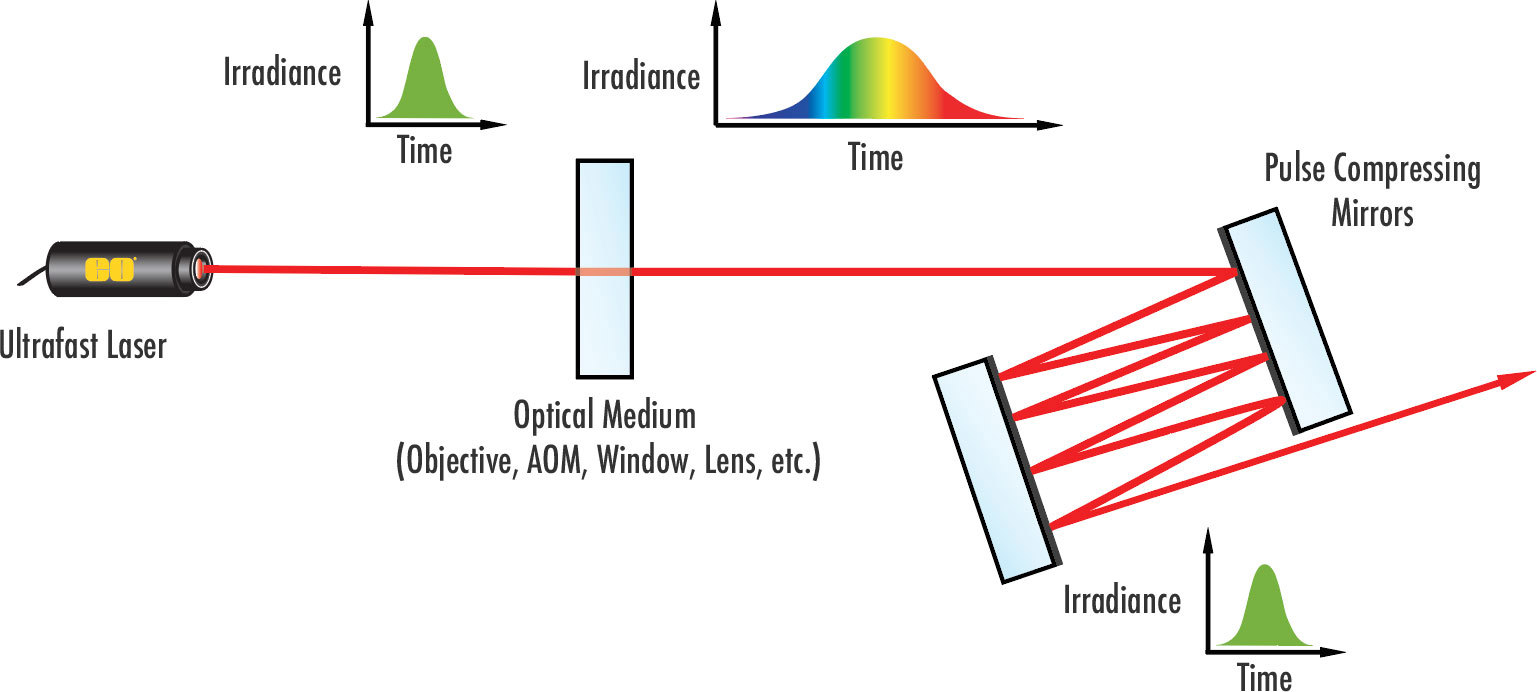

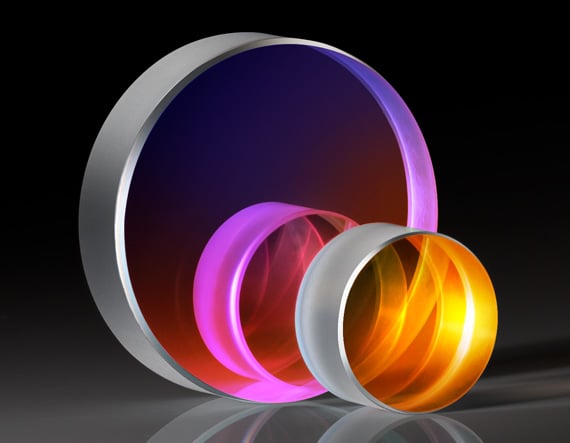

Dielectric ultrafast highly-dispersive mirrors are an ideal solution for compact, alignment-insensitive, and broadband dispersion compensation |

|

|

These high dispersion and low loss mirrors are used for pulse compression applications, such as chirped pulse amplification |

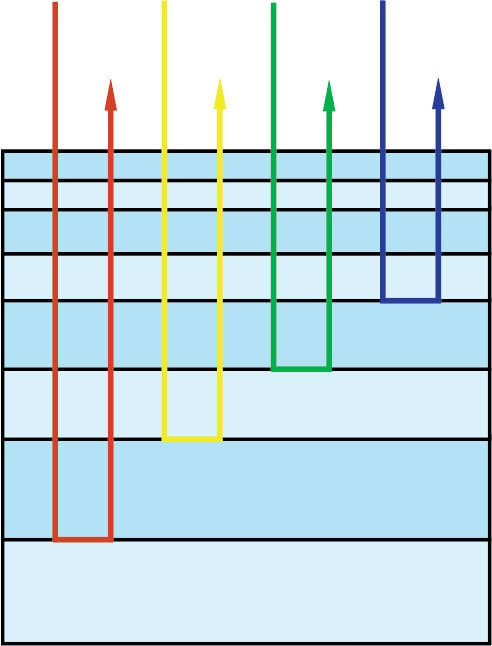

Ultrafast highly-dispersive mirrors are critical for pulse compression and dispersion compensation in ultrafast laser applications. Ultrafast lasers emit extremely short pulses with durations of picoseconds, femtoseconds, or attoseconds, and, due to the Heisenberg uncertainty principle, transform-limited pulses reaching their lower limit for pulse duration have a wide bandwidth covering a considerable wavelength spread (Figure 1). Dispersion of this wide bandwidth as it transmits through optical media, such as objectives, windows, or lenses, stretches out the pulse duration of ultrafast pulses, making dispersion compensation an important part of ultrafast laser applications.

Figure 1: The shorter the pulse of an ultrafast laser, the wider its wavelength bandwidth

The short pulse durations and high peak powers of ultrafast lasers are highly advantageous for a number of applications including materials processing, micromachining, biomedical applications, nonlinear imaging and microscopy, defense, and communications. In materials processing and micromachining, ultrafast lasers allow for better dimensional tolerances, reduce damage to surrounding areas, and eliminate post-processing steps.1 The short pulse durations of ultrafast lasers also lead to less trauma in medical laser applications, such as LASIK eye surgery, while reducing the need for sterilization and anesthetics (Figure 2).2

Figure 2: Ultrafast lasers are used for bladeless LASIK eye surgery to increase patient safety, decrease the risk of infection, and improve precision

Chromatic dispersion describes the dependence of the phase velocity (or speed) of light in an optical medium on its optical frequency or wavelength. Most materials used for optical components exhibit positive dispersion, meaning that longer wavelengths will have a higher phase velocity than short wavelengths (Figure 3). This elongates the pulse duration of ultrafast pulses in a process known as positive chirp, which is detrimental in ultrafast applications.

Figure 3: Dispersion leads to the broadening of ultrafast laser pulses. AOM stands for acousto-optic modulator, which is a component that allows lasers to emit a pulsed output

However, this can be compensated by optical components, such as multilayer dielectric mirrors, that feature negative dispersion, in which shorter wavelengths have a higher phase velocity than long wavelengths. This balances out the positive dispersion that occurred earlier in the system, resulting in pulse compression for optimal performance (Figure 4).

Figure 4: Pulse compressing with negative dispersion can cancel out the positive dispersion ultrafast pulses experience from transmitting through optical media

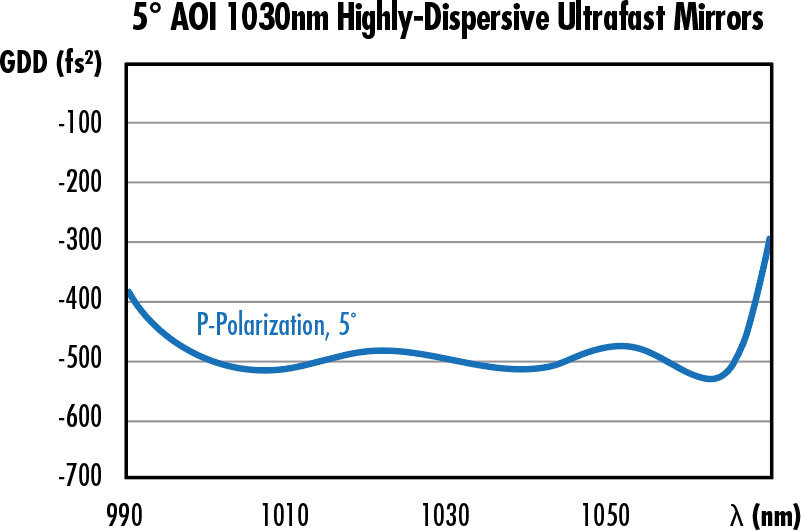

When considering how dispersion affects ultrafast laser systems, it is necessary to understand group delay and group delay dispersion (GDD). The group delay of an optical component is the derivative of the change in the phase of the electric field of the radiation with respect to its angular frequency. GDD is defined as the derivative of the group delay, or the second derivative of the spectral phase, with respect to frequency. The GDD per unit length is known as the group velocity dispersion (GVD). GDD is typically given in units of fs2 while GVD is given in units of fs2/mm. Pulse compressing optics typically have a negative GDD with a large magnitude in order to compress positively chirped pulses. For more information on dispersion and GVD, please read our Dispersion application note.

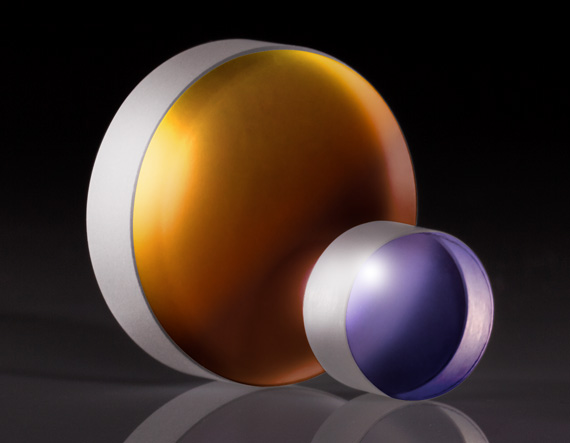

There are several different types of available pulse compressing optics for ultrafast dispersion compensation, including gratings and prisms. However, highly-dispersive mirrors are advantageous for pulse compression due to their compact size, low loss, and highly-negative dispersion over a large bandwidth, which could be used for alignment-insensitive pulse compressors that compensate for GDD as well as third- and high-order dispersion.3

To understand how ultrafast highly-dispersive mirrors function it is important to understand two other types of mirrors: Gires-Tournois interferometer (GTI) mirrors and chirped mirrors. GTI mirrors utilize resonance to provide angle-dependent negative GDD for intracavity dispersion control in ultrafast lasers. However, GTI mirrors provide negative GDD over a very limited bandwidth and introduce some high-order dispersion.

On the other hand, chirped mirrors provide a controlled negative GDD through the wavelength dependent penetration depth of the laser pulse. The layer thicknesses in their dielectric coating increase as light penetrates into the coating. This causes shorter wavelengths to have shorter penetration depths into the coating than long wavelengths, essentially allowing long wavelengths to “catch up” to short wavelengths and experience a larger group delay (Figure 5). However, in these simple multilayer dielectric structures, the discrete switching between different layer thicknesses leads to oscillations in the GDD as a function of wavelength, similar to the oscillations experienced in a Febry-Perot resonator.

Figure 5: Chirped mirrors have a variable layer thickness that causes negative dispersion by allowing longer wavelengths to penetrate further into the coating than short wavelengths

Ultrafast highly-dispersive mirrors counter this issue through the combination of wavelength-dependent penetration effect, similar to that of traditional chirped mirrors, and a multi-resonance effect knows as multi-GTI.3 This optimized combination of penetration and resonance effects allows higher GDD values and low loss over broad bandwidth without increasing the thickness of the multilayer coating structure.

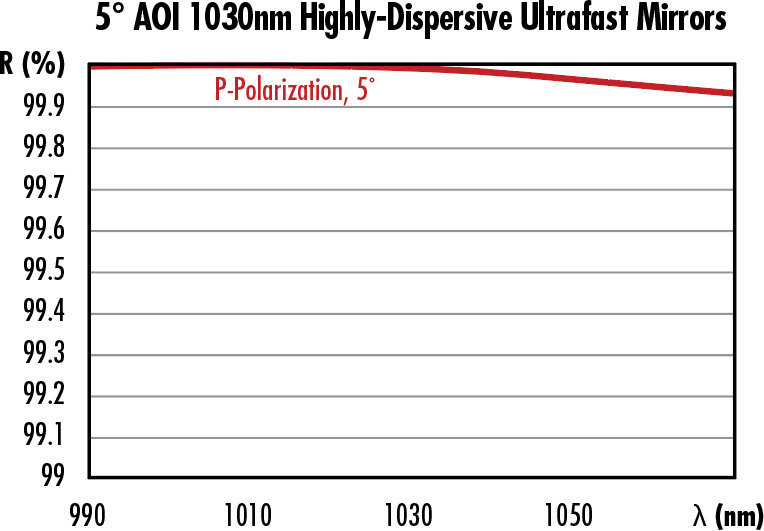

Traditional pulse compression optics, such as gratings or dispersive prisms, could also be used for ultrafast pulse compression and dispersion compensation. However, highly-dispersive mirrors are more advantageous due to their compact size, low loss, and negative GDDs with large magnitudes over a large bandwidth (Figures 6 and 7). They are used for all-mirror, alignment-insensitive pulse compressors that compensate for GDD as well as third- and high-order dispersion.

Figure 6: Reflectivity curve of the 1030nm Highly-Dispersive Ultrafast Mirrors

Figure 7: Group delay dispersion (GDD) curve of the 1030nm Highly-Dispersive Ultrafast Mirrors

Typical chirped pulse amplification (CPA) lasers, which amplify ultrafast pulses to high optical peak intensities while preventing excessive nonlinear pulse distortions or damage to the gain medium, rely on stretching and compressing pulses before and after amplification. Therefore, compressive optics such as ultrafast highly-dispersive mirrors are decidedly important for CPA lasers.

Optical components for ultrafast lasers face a unique set of challenges that must be overcome to ensure high pulse quality and to maximize system performance.

Edmund Optics® offers a variety of different ultrafast highly-dispersive mirrors for different common ultrafast laser wavelengths.

800nm Highly-Dispersive Ultrafast Mirrors feature a multilayer ultrafast chirped coating and a GTI coating to achieve a GDD of -1300fs2 at 5° angle of incidence (AOI) and >99.8% reflection (p-polarization) between 730-830nm. The highly-dispersive coating design provides control of third and higher order dispersions with high beam stability.

Learn More

1030nm Highly-Dispersive Ultrafast Mirrors offer a GDD of -1000 fs2 at a 7° angle of incidence (AOI) and >99.8% reflection (p-polarization) across a 60nm bandwidth, making them optimal for Yb:doped fiber laser pulse compression and dispersion compensation.

Learn More

1030nm Highly-Dispersive Broadband Ultrafast Mirrors feature a GDD of -200 fs2 at 5° AOI and >99.8% reflection of p-polarization between 950 - 1120nm. They are optimal for pulse compression and dispersion compensation of ultrafast near infrared (NIR) lasers including ultrafast Yb:doped fiber lasers.

Learn More

2μm Highly-Dispersive Broadband Ultrafast Mirrors are ideal for intracavity dispersion compensation and 99% reflectivity from 2000-2200nm.

Learn More How does group delay dispersion (GDD) relate to first order and higher order dispersion?

How does group delay dispersion (GDD) relate to first order and higher order dispersion?

Why do ultrafast highly-dispersive mirrors have such low angles of incidence (AOIs)?

Why do ultrafast highly-dispersive mirrors have such low angles of incidence (AOIs)?

The low AOI of ultrafast highly-dispersive mirrors allow for reflections between multiple mirrors, so several mirrors will be used at once for maximum dispersion compensation and pulse compression.

Do the short pulse durations of ultrafast lasers impact the laser induced damage threshold of ultrafast optics?

Do the short pulse durations of ultrafast lasers impact the laser induced damage threshold of ultrafast optics?

Yes, short ultrafast pulses interact with optical coatings and substrates in a way that is different from other laser pulses, leading to different damage mechanisms. For more information, please read our LIDT for Ultrafast Lasers application note.

At what pulse duration is a laser considered to be “ultrafast?”

At what pulse duration is a laser considered to be “ultrafast?”

Laser pulses with picosecond, femtosecond, and attosecond pulse durations (<100ps) are typically considered to be “ultrafast.”

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics India Private Limited, #267, Greystone Building, Second Floor, 6th Cross Rd, Binnamangala, Stage 1, Indiranagar, Bengaluru, Karnataka, India 560038

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act